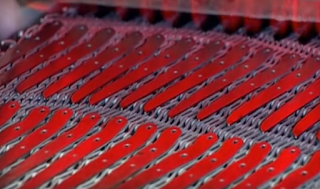

Tempering is process use to increase toughness of metal.

This process is perform on iron based material and usually used after hardening process for reducing excess hardness.

This process is done by heating metal below critical point and usually cool by air. There are some steel that are quenched after tempering process for avoiding brittleness.

Tensile strength of harden steel may increase when tempering process is done about 450°F. And above this temperature it decrease.

Hardness is reduce according to temperature at which tempering process done.

Note : Only for high-speed steel material, hardness is increase during tempering process about temperature 1550°F.

Minimum time required for 1 mm thick material for tempering process is : 1 Hour.

Time increase for every addition of 1 mm is : 1 Hour.

Tempering increases softness, ductility, malleability, and impact resistance.

This process is perform on iron based material and usually used after hardening process for reducing excess hardness.

This process is done by heating metal below critical point and usually cool by air. There are some steel that are quenched after tempering process for avoiding brittleness.

Tensile strength of harden steel may increase when tempering process is done about 450°F. And above this temperature it decrease.

Hardness is reduce according to temperature at which tempering process done.

Note : Only for high-speed steel material, hardness is increase during tempering process about temperature 1550°F.

Minimum time required for 1 mm thick material for tempering process is : 1 Hour.

Time increase for every addition of 1 mm is : 1 Hour.

Tempering increases softness, ductility, malleability, and impact resistance.

Comments

Post a Comment